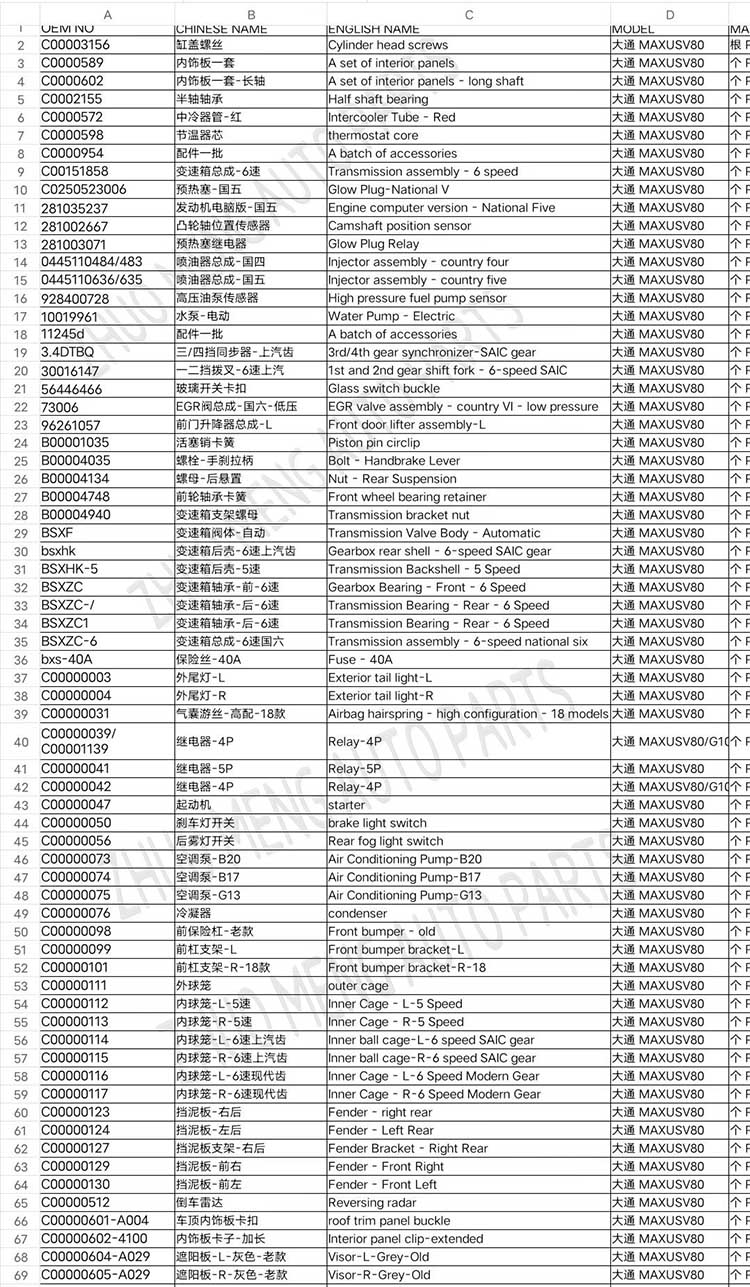

Farashin masana'anta SAIC MAXUS V80 C00014635 Pan mai - Kasa IV

Takaitaccen Bayani:

Cikakken Bayani

Tags samfurin

Bayanan samfuran

| Sunan samfuran | Pan mai |

| Aikace-aikacen samfuran | SAIC MAXUS V80 |

| Samfuran OEM NO | Farashin 00014635 |

| Org na wuri | YI A CHINA |

| Alamar | CSSOT / RMOEM/ORG/COPY |

| Lokacin jagora | Hannun jari, idan ƙasa da PCS 20, na al'ada wata ɗaya |

| Biya | TT Deposit |

| Kamfanin Brand | CSSOT |

| Tsarin aikace-aikace | Tsarin wutar lantarki |

Ilimin samfuran

jika

Rigar Sump

kwanon mai

Galibin motocin da ake gani a kasuwa jika ne na mai.Dalilin da ya sa aka ba su sunan kwanon mai shi ne, ƙugiyar ƙugiya da babban ƙarshen sandar haɗin injin ɗin suna nutsewa cikin man mai na kaskon mai sau ɗaya kowane juyi na crankshaft.Haka nan kuma saboda saurin aiki da mashin din da ake yi, a duk lokacin da aka nutsar da magudanar ruwa a cikin tafkin mai da saurin gaske, za a taso wasu fantsama na mai da hazo mai da za a rika shafawa a kurmi da kurmin dajin, wanda shi ne. ake kira fesa lubrication.Ta wannan hanyar, akwai wasu buƙatu don matakin ruwa na mai mai a cikin kwanon mai.Idan ya yi ƙasa da ƙasa, ba za a iya nutsar da crankshaft crankshaft da babban ƙarshen sandar haɗawa a cikin mai mai mai ba, wanda ke haifar da ƙarancin lubrication da santsi mai santsi, sandar haɗawa da daji mai ɗaukar nauyi.;Idan matakin man mai ya yi tsayi da yawa, za a nutsar da na'urar gaba ɗaya, wanda zai ƙara juriya na jujjuyawar crankshaft, wanda a ƙarshe zai haifar da raguwar aikin injin.

Irin wannan hanyar lubrication yana da tsari mai sauƙi kuma baya buƙatar ƙarin tankin mai, amma karkatar da abin hawa bai kamata ya kasance mai girma ba, in ba haka ba zai haifar da haɗarin silinda mai ƙonewa saboda gazawar mai da zubar mai.

bushewa

Dry Sump

Ana amfani da busassun sumps a cikin injunan tsere da yawa.Ba ya adana mai a cikin mazugi, daidai, babu tarin mai.Fuskokin waɗannan motsin a cikin akwati ana shafawa ta hanyar latsa mai ta hanyar bango ɗaya bayan ɗaya.Tun da busasshen injin ɗin ya soke aikin ajiyar mai na rijiyar mai, tsayin rijiyar mai ya ragu sosai, kuma tsayin injin ɗin yana raguwa.Babban fa'idar shi ne cewa yana guje wa mummunan al'amura na rigar sump da ke haifar da tsananin tuƙi.

Duk da haka, duk matsi na man mai yana fitowa daga famfo mai.Ana haɗa wutar lantarki ta famfo mai ta hanyar jujjuyawar crankshaft.Ko da yake a cikin injin daskarewa, ana kuma buƙatar famfo mai don samar da lubrication na camshaft.Amma wannan matsin lamba kadan ne, kuma famfon mai yana bukatar wuta kadan.A cikin busassun injunan sump, duk da haka, ƙarfin wannan matsi na matsi yana buƙatar girma sosai.Kuma girman famfon mai shima ya fi na famfon mai na injin jika.Don haka, famfon mai yana buƙatar ƙarin iko a wannan lokacin.Wannan kamar injin ne mai caji, famfon mai yana buƙatar cinye wani yanki na ƙarfin injin ɗin.Musamman a cikin matsanancin gudu, lokacin da injin ya karu, ƙarfin motsi na sassa na juzu'i yana ƙaruwa, kuma ana buƙatar ƙarin mai don shafawa, don haka famfo mai yana buƙatar samar da ƙarin matsi, kuma amfani da wutar lantarki yana ƙaruwa.

Babu shakka, irin wannan ƙirar ba ta dace da injunan motocin farar hula na yau da kullun ba, saboda yana buƙatar rasa wani ɓangare na ƙarfin injin, wanda ba wai kawai yana shafar ƙarfin wutar lantarki bane, amma kuma ba ya da amfani don haɓaka tattalin arziki.Saboda haka, busassun sump an sanye shi da manyan injuna ko injuna masu ƙarfi, kamar waɗannan motocin wasanni waɗanda aka haifa don tuƙi mai ƙarfi.Alal misali, Lamborghini ya ɗauki ƙirar busasshen mai.Don shi, yana da mahimmanci don inganta tasirin lubrication a iyaka da samun ƙananan cibiyar nauyi, kuma ana iya rama asarar wutar lantarki ta hanyar haɓaka ƙaura da sauran fannoni.Amma game da tattalin arziki Jima'i wani abu ne da wannan samfurin baya buƙatar la'akari da shi kwata-kwata.

Aiki da kulawa

Famfu na allurar man dizal wani muhimmin bangare ne na tsarin samar da man dizal, kuma yanayin aikinsa yana shafar wutar lantarki, tattalin arziki da amincin injin din diesel.Madaidaicin kulawa shine muhimmin abin da ake buƙata don tabbatar da aiki na yau da kullun na famfon allurar mai da tsawaita rayuwarsa.Wadannan “abubuwa goma” masu zuwa suna koya muku yadda ake kula da famfon allurar man dizal janareto:

1. Don da kyau kula da kayan haɗi na famfo allurar man fetur.

Gefen murfin famfo jiki, mai dipstick, refueling toshe (mai numfashi), man zube bawul, man pool dunƙule toshe, man matakin dunƙule, man famfo kayyade aron kusa, da dai sauransu dole ne a kiyaye m.Wadannan na'urorin haɗi suna taka muhimmiyar rawa a cikin aikin famfo allurar mai.muhimmiyar rawa.Misali, murfin gefe na iya hana kutsawa na ƙazanta irin su ƙura da ruwa, na'urar numfashi (tare da tacewa) na iya hana lalacewar mai yadda ya kamata, kuma bawul ɗin ambaton mai yana tabbatar da cewa tsarin mai yana da takamaiman matsa lamba kuma ya aikata. kada ku shiga iska.Don haka, ya zama dole a ƙarfafa kiyaye waɗannan na'urorin haɗi, da gyara ko musanya su cikin lokaci idan sun lalace ko suka ɓace.

2. A kai a kai bincika ko yawan mai da ingancin mai a cikin tafkin mai na famfun allurar mai sun cika buƙatun.

Kafin a fara injinan dizal, sai a duba yawan man da ke cikin famfon allurar mai a kowane lokaci (sai dai famfon allurar mai da injin ya tilasta masa mai) don tabbatar da cewa adadin man ya wadatar kuma ya isa. ingancin yana da kyau.In ba haka ba, zai haifar da farkon lalacewa na plunger da nau'in bawul ɗin mai kanti, wanda zai haifar da rashin isasshen ƙarfin injin diesel, wahalar farawa, kuma a cikin lokuta masu tsanani, lalata da lalata na plunger da nau'in bawul ɗin mai kanti.Sakamakon zubewar famfon mai na cikin gida, rashin aiki na bawul ɗin mai, da lalacewa tafe da cakuɗen famfon mai, da lalacewar zoben rufewa, man dizal zai zubo a cikin tafkin mai ya narke mai.Don haka, ya kamata a canza shi cikin lokaci gwargwadon ingancin mai.Ana tsaftace tankin sosai don cire sludge da sauran datti a kasan tankin mai, in ba haka ba man zai lalace bayan ɗan lokaci da amfani.Adadin mai kada yayi yawa ko kadan.Yawan man fetur a cikin gwamna zai iya haifar da "gudu" na injin dizal.Dan kadan mai zai haifar da rashin lubrication mara kyau.Tushen man fetur ko dunƙule jirgin mai zai yi nasara.Bugu da kari, idan injin dizal ya dade ba a yi amfani da shi ba, ya zama dole a duba ko akwai datti kamar ruwa da man dizal a cikin mai a cikin tafkin mai.Yankakken tsatsa sun makale kuma an goge su.

3. Duba akai-akai da daidaita wadatar mai na kowane silinda na famfon allurar mai.

Sakamakon lalacewa na plunger coupler da na'ura mai ba da wutar lantarki na man dizal, zubar da man dizal na ciki zai haifar da raguwa ko rashin daidaituwa, wanda zai haifar da wahala wajen fara injin dizal, rashin isasshen wutar lantarki, karuwar yawan man fetur. , da aiki mara ƙarfi.Saboda haka, wajibi ne a kai a kai duba da daidaita samar da man fetur na kowane Silinda na man fetur allurar famfo don tabbatar da aiki na dizal engine ikon.A zahirin amfani, ana iya tantance adadin adadin man fetur na kowane Silinda ta hanyar lura da hayakin janareta na diesel, sauraron sautin injin, da kuma taɓa yanayin zafin na'urar.

4. Yi amfani da daidaitattun bututun mai mai ƙarfi.

A lokacin aikin samar da man fetur na famfun allurar mai, saboda damtsewar man dizal da kuma elasticity na babban bututun mai, man dizal mai matsananciyar matsa lamba zai haifar da hauhawar matsin lamba a cikin bututun, kuma yana ɗaukar ɗan lokaci kaɗan don haka. matsa lamba don watsawa a cikin bututu.Adadin dai bai dace ba, injin dizal ɗin yana aiki daidai gwargwado, kuma ana zaɓar tsayi da diamita na bututun mai mai matsananciyar matsa lamba bayan an yi lissafi.Don haka, lokacin da babban bututun mai na wani silinda ya lalace, ya kamata a canza bututun mai na daidaitaccen tsayi da diamita na bututu.A zahirin amfani, saboda rashin daidaitattun bututun mai, a maimakon haka, ana amfani da sauran bututun mai, ba tare da la’akari da tsayi da diamita na bututun mai ba, ta yadda tsayin da diamita na bututun mai ya bambanta sosai.Ko da yake ana iya amfani da shi a cikin gaggawa, zai kai ga samar da mai na Silinda.Canjin kusurwar gaba da adadin samar da mai yana sa injin gabaɗayan aiki mara ƙarfi, don haka daidaitaccen bututun mai dole ne a yi amfani da shi.

5. A kai a kai duba yanayin hatimi na ma'aunin bawul akan na'ura.

Bayan famfon allurar mai ya yi aiki na wani ɗan lokaci, ta hanyar duba yanayin rufe bawul ɗin mai, za a iya yanke hukunci mai tsauri kan lalacewa na plunger da yanayin aikin famfo mai, wanda ke da fa'ida don tantancewa. hanyar gyarawa da kulawa.Lokacin dubawa, cire haɗin haɗin bututun mai mai matsa lamba na kowane Silinda, kuma yi amfani da famfon mai na hannu na famfon isar da mai don fitar da mai.Idan mai ya fito daga mahaɗin bututun mai a saman fam ɗin allurar mai, hakan yana nufin ba a rufe bawul ɗin mai da kyau (hakika, idan bututun mai ya karye, to shima idan hakan ta faru). idan akwai mummunan hatimi a cikin multi-cylinder, ya kamata a cire famfo mai allurar man fetur sosai kuma a kiyaye shi, kuma a maye gurbin ma'aurata.

6. Maye gurbin sawa plunger da man bawul na kanti a cikin lokaci.

Idan aka gano cewa injin dizal ke da wuya wutar ta ragu, kuma yawan man da ake amfani da shi ya karu, kuma famfon allurar mai da injin mai ba a inganta ba ta hanyar daidaita famfon allurar mai, da injin allurar mai da mai. ya kamata a tarwatsa bawul ɗin fita kuma a duba.Idan plunger da bawul kanti na man fetur suna sawa zuwa wani matsayi, ya kamata a maye gurbinsu cikin lokaci, kada ku dage a sake amfani da su.Matsalolin fara aikin injin dizal, yawan amfani da man fetur, rashin isassun wutar lantarki da sauran hasarar da lalacewa na kayan haɗin gwiwar ke haifarwa ya zarce kuɗin da ake kashewa wajen maye gurbin na'urorin haɗin gwiwa, kuma wutar lantarki da tattalin arzikin injin dizal za su inganta sosai bayan maye gurbinsu.Sauyawa sassa.

7. A rika amfani da man dizal a tace shi yadda ya kamata domin tabbatar da cewa man dizal din da ke shiga famfon allurar mai ya yi tsafta sosai.

Gabaɗaya magana, injinan dizal suna da buƙatu mafi girma don tace diesel fiye da injinan mai.Man dizal wanda ya cika maki da ake buƙata ya kamata a zaɓi don amfani, kuma yakamata a haɗe shi na akalla sa'o'i 48.Ƙarfafa tsaftacewa da kula da tace diesel, tsaftacewa ko maye gurbin abubuwan tacewa a cikin lokaci;tsaftace tankin dizal a cikin lokaci bisa yanayin yanayin aiki, cire sludge da danshin da ke ƙasan tankin mai, kuma duk wani ƙazanta da ke cikin dizal zai yi tasiri a kan bututun allurar mai da fitar da mai.Mummunan lalata ko lalacewa na bawul ma'aurata da sassan watsawa.

8. Duba akai-akai kuma daidaita kusurwar samar da man fetur gaba na famfon allurar mai da kusurwar tazarar man fetur na kowane Silinda.

A lokacin amfani da shi, saboda sassaukar da ƙusoshin haɗin gwiwa da lalacewa na camshaft da sassan jikin jiki, ana canza kusurwar gaba na samar da mai da tazarar tazarar man kowane Silinda, wanda ke sa ƙonewar diesel ya yi muni, kuma iko da tattalin arzikin injin diesel.Ayyukan aiki sun lalace, kuma a lokaci guda, yana da wuya a fara farawa, rashin kwanciyar hankali a cikin aiki, ƙarar ƙararrawa da zafi.A cikin ainihin amfani, yawancin direbobi suna kula da dubawa da daidaitawa na gabaɗayan samar da man fetur gaba ɗaya, amma yin watsi da dubawa da daidaitawar kusurwar samar da man fetur (wanda ya haɗa da daidaitawar famfo guda ɗaya na samar da man fetur).Duk da haka, saboda lalacewa na camshafts da na'urori masu watsawa, samar da mai na sauran silinda ba lallai ba ne, wanda zai haifar da matsala wajen fara injin dizal, rashin isasshen wutar lantarki, da rashin kwanciyar hankali, musamman ga famfon allurar mai. wanda aka dade ana amfani dashi.An ce ya kamata a mai da hankali sosai wajen duba tare da daidaita kusurwar samar da mai.

9. Don bincika kullun camshaft akai-akai.

Amincewar axial na camshaft na famfon allurar mai yana da tsauri sosai, gabaɗaya tsakanin 0.03 da 0.15mm.Idan izinin ya yi girma da yawa, zai ƙara tasirin sassan watsa abin nadi akan aikin cam ɗin, ta haka yana haɓaka farkon lalacewa na cam ɗin da canza wadatar.Oil gaba kusurwa;Ƙaƙƙarfan camshaft da radial clearance suna da girma da yawa, wanda ke da sauƙin sa camshaft ɗin ya yi aiki ba daidai ba, madaidaicin ƙarar mai yana girgiza, kuma ƙarar samar da mai yana canzawa lokaci-lokaci, wanda ke sa injin dizal ya yi rauni, don haka ya zama dole duba da daidaita akai akai.Lokacin da izinin axial na camshaft ya yi girma, ana iya ƙara shims a bangarorin biyu don daidaitawa.Idan sharewar radial ya yi girma sosai, gabaɗaya ya zama dole don maye gurbin sabon samfurin.

10. A kai a kai duba lalacewa na hanyoyin da suka dace da kuma gyaran ƙugiya.

Mahimman hanyoyin maɓalli da kusoshi galibi suna nuni ne ga hanyoyin maɓalli na camshaft, hanyoyin haɗin flange keyways (famfon mai da ke watsa ƙarfi tare da haɗin gwiwa), maɓallan madauwari da maɓalli masu daidaitawa.An daɗe ana amfani da hanyar camshaft keyway, flange keyway da semicircular key na famfon allurar man fetur, kuma hasken sun ƙare, wanda ya sa maɓalli ya fi fadi, maɓallin semicircular ba a shigar da shi ba, da kusurwar gaba na mai. canje-canjen wadata;a cikin yanayi mai tsanani, maɓallin yana buɗewa, yana haifar da gazawar watsa wutar lantarki., don haka wajibi ne a bincika akai-akai da gyara ko maye gurbin sawa a cikin lokaci.

Matakan kariya

Ƙarfafa Diesel

1. O-ring na injector ya lalace;

2. Rashin atomization na injector, diga mai;

3. Rashin shigar da injector mara kyau;

4. Ba a maye gurbin O-ring ba lokacin da aka sake shigar da injector.

Adana janareta na Cummins yakamata a kula da:

1) Wurin ajiya na tankin mai dole ne ya kasance lafiya don hana wuta.Ya kamata a sanya tankin mai ko gangunan mai a wurin da ake iya gani shi kaɗai, nesa da injin janareta na diesel, kuma an hana shan taba.

2) Yawan man fetur a cikin tankin mai ya kamata ya tabbatar da wadata yau da kullum.

3) Bayan an sanya tankin mai, mafi girman matakin mai ba zai iya zama sama da mita 2.5 sama da tushe na saitin janareta na diesel ba.Idan matakin man babban ma'ajiyar mai ya haura mita 2.5, ya kamata a kara tankin mai a kullum tsakanin babban ma'ajiyar mai da na'urar don yin matsin isar da mai kai tsaye.Ba fiye da mita 2.5 ba.Ko da injin dizal ya kashe, ba a barin man ya shiga cikin injin dizal ta layin shigar mai ko kuma layin allurar mai ta hanyar nauyi.

4) Ba a yarda da juriya a tashar mai ta wuce ƙimar da aka kayyade akan duk takaddun bayanan aikin injin dizal lokacin amfani da kashi mai tsafta.Wannan ƙimar juriya ta dogara ne akan rabin man fetur a cikin tankin mai.

5) Juriya dawo da man fetur ba dole ba ne ya wuce ƙayyadaddun bayanai akan takaddar bayanan aikin injin dizal da aka yi amfani da shi.

6) Haɗin bututun mai na dawo da mai bai kamata ya haifar da tashin hankali ba a cikin bututun mai.

Nunin MU

Samfura masu alaƙa